Laminating

Laminating lines with roller lamination

With Menzel laminating machines your production is strengthened by reliable and long-lasting equipment. Various processes can be used for hot lamination with electrically operated or thermal oil heated rollers: direct lamination by melting the materials, lamination with adhesion promoters, such as melting powder, and hot embossing lamination using embossing rollers.

We also offer laminating processes based on hotmelt application, adhesive films or dispersion adhesives. When selecting the optimum laminating machine for our customers' individual requirements, we take into account both the nature of the material and the general conditions of your production.

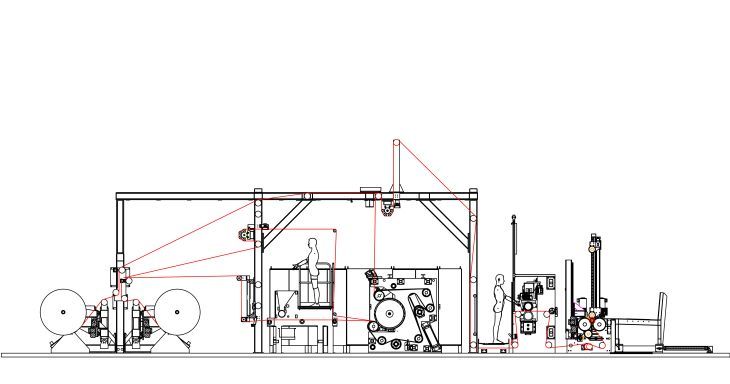

Example layout of a roller laminating line

Laminating line with spray application of hotmelt for nonwovens

Laminating line with heated rollers for roofing underlays

Laminating line for PTFE membranes and filter materials

Laminating line for technical fabrics

Laminating line for impact sound insulation material

Universal laminating machine for foils, metallized films, paper and non-woven materials.

Laminating line for sealing materials

Roller lamination for the production of inner lid seals

Laminating line Hotmelt laboratory line

Laminating lines with belt laminator

Menzel laminating lines with belt calender are the perfect solution for the production of multilayer composites made of nonwoven, textile, foil, aluminum foil, silicone foil (OPW Airbag) and paper. A heating roll with double shell construction ensures uniform temperature over the entire surface. The maximum fabric width is 3,600 mm. The fabric feed to the belt calender is carried out via our proven MENZEL web guiding elements, which thus ensure an ideal and crease-free feed. By means of supplementary aggregates you can, for example, apply dispersion adhesives to a substrate or activate already existing pre-coatings by IR heating fields.

Example layout of a belt laminating line for painting fleece

Example layout of a belt laminating line for insulation products

Belt laminating line for insulation products

Belt laminating calender

Laminating line as a special version for OPW airbag fabric. For this purpose, silicone film is used for direct lamination on the airbag fabric.

Belt laminating line for technical products

Lamination of two different material webs with different properties by means of adhesive under variable pressure and required temperature.

Aggregates and accessories for laminating lines

We realize YOUR project!

Do you need more information? We look forward to hearing from you!