Winding

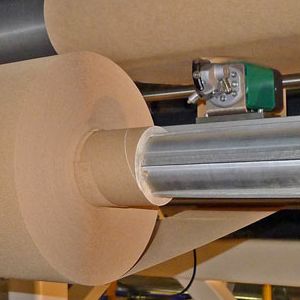

Rolls with a diameter of up to 2 meters can be optimally wound on the Menzel large-diameter bobbin system.

Our center winders can also be adapted to sensitive material and are available as mobile or fixed units.

When large and heavy rolls have to be wound on small core diameters, our carrier roll winders with widths of up to 15 meters are used.

Contact winders combine the advantages of circumferential winders and center winders to produce tight windings.

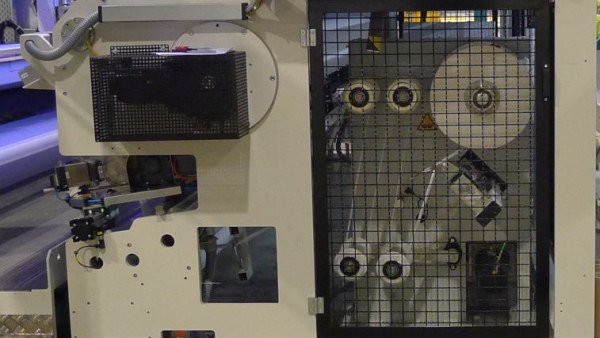

Turret winder: Without stopping the line, the roll can be changed at full production speed.

Special Winder

We also realize special winders for the individual applications of our customers.

There are various solutions from Menzel for edge trim disposal. Learn more about our edge trim winders and discharge systems here.

Menzel splice stations are offered as manual or automatic splice stations, with clamping beam or cross cutter.

Aggregates and accessories for winding

We realize YOUR project!

Do you need more information? We look forward to hearing from you!