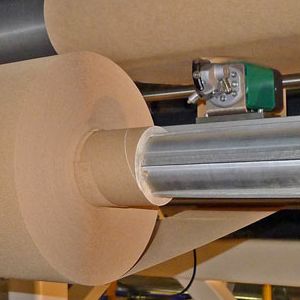

A-Frame Winder

On the a-frame system developed by Menzel, rolls with a diameter of up to 2 meters can be optimally wound with the aid of specially designed center winders. This can be done on special stationary winding frames as well as on mobile docking carriages. The advantage of this system is the long running times and short changeover times. Winding machines for large reels can either be built as a system with manual roll change or with fully automatic reel change.

Fully automatic a-frame winder 2 winding stations

Fully automatic large reel winder for films or nonwovens with and without carrier fabric.

Automatic a-frame winder for nonwoven, 2 winding stations

A-frame winder with fabric accumulator and two winding positions to ensure quick roll change.

A-frame winder, 2 winding stations

A-Frame winder for thermoforming sheet with two winding stations, draw unit, cross cutter and fabric accumulator.

A-frame winder woven goods/Raschel machine

The a-frame winder at the outlet of a Raschel machine winds elastic knitted fabric onto a docking car.

Unwinding platform edge-controlled

An edge control enables straight-edge winding, which is achieved by traversing the winding stand.

Fabric inlet wet machines with trough

Continuous fabric inlet with stainless steel storage trough for wet finishing applications

Folding machine

This outlet with winder and cuttling was designed as a combination for wet machines.

Aggregates and accessories for winding

We realize YOUR project!

Do you need more information? We look forward to hearing from you!