Wet Finishing

Washing Machines

A clean business. One of the first steps in textile finishing is washing or desizing the raw material. On Menzel washing systems, fiber preparations or sizing agents - indispensable for the process of weaving, knitting or warp knitting - are washed out of the textile. Whether cotton jersey for fashion or sportswear, elastic warp-knitted fabrics with or without Lycra for functional underwear or even textiles for the automotive industry, Menzel always offers the perfect washing solution.

Also as a unit for upholstery fabrics or as a component of a bleaching or mercerizing machine, Menzel open-width washing machines are always the backbone and essential element of any continuous textile finishing line.

Menzel offers a variety of individual solutions on the platform of classic washing systems such as roller skids, tower washing machines or screen drum washing machines for fabrics sensitive to tension. From woven fabrics to tulle, Menzel washing machines are always the first choice.

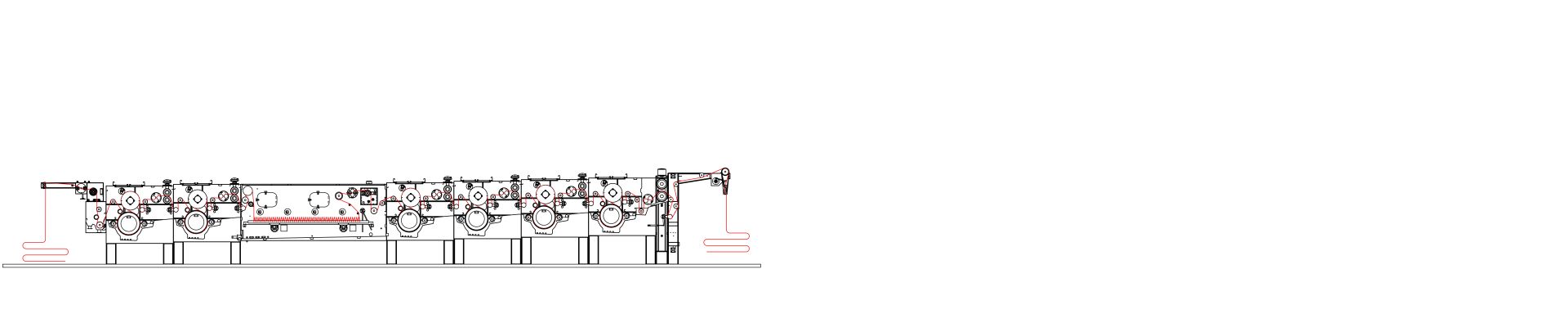

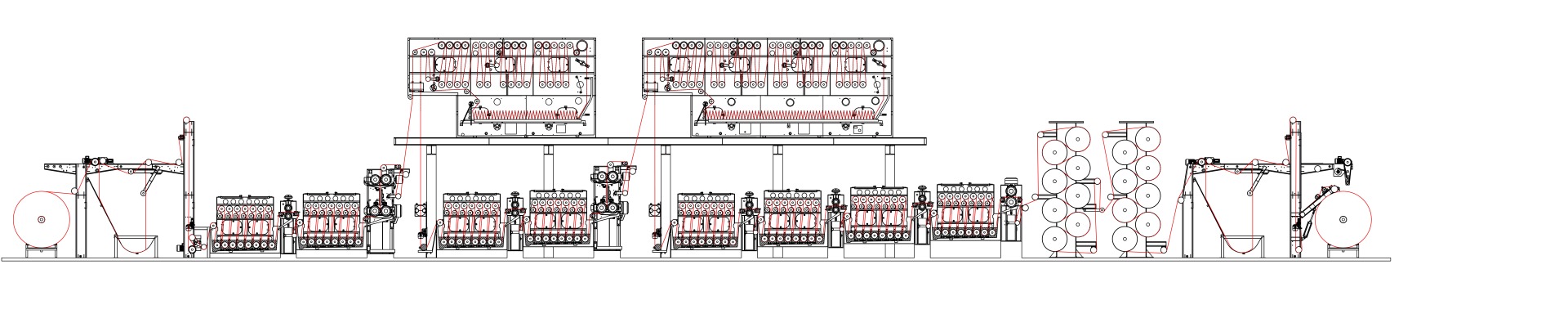

Washing Machine Compact Flow

OPTIWASH pressure afterwash

The washing machine for post-print washing with individual dwell units MEGALAX and OPTIDWELL. Alternatively, for combined processes the machine can be designed with OPTISTEAM KF for knitted fabrics.

Washing Machine Combi

The Menzel combination washing plant with high-performance washing compartments and the OPTIPREG impregnation box. With this machine, common washing processes as well as hot and cold bleaching processes can be realized.

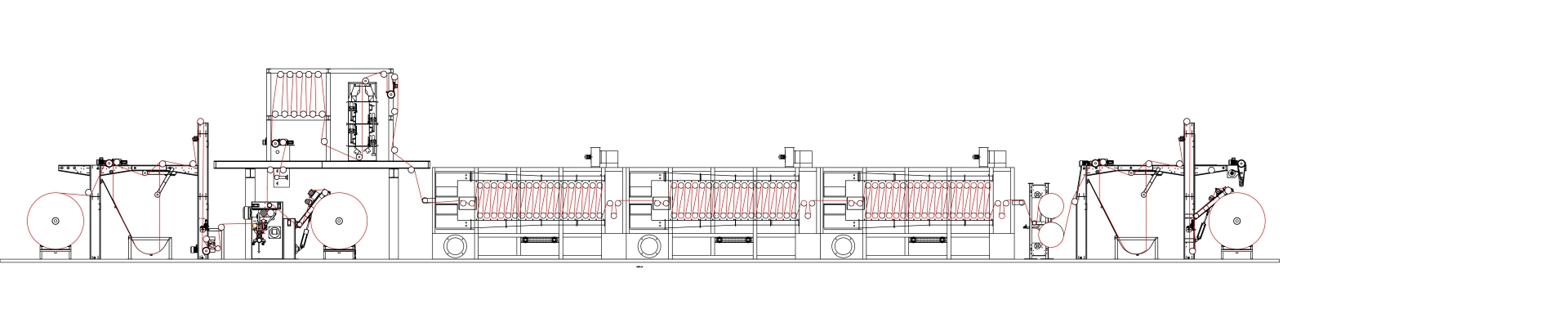

Washing machine knitted fabric

The Menzel knitted fabric washing machine with drum washing compartments for the treatment of delicate fabrics. It offers highest washing performance with low tension fabric guidance from unwinding to winding - ideal for your knitted fabric.

Washing machine with dwell compartment

The Menzel knitwear washing plant with OPTISPLASH drum washing compartments, supplemented by an additional dwell zone OPTIDWELL for the treatment of delicate fabrics. This unit offers highest washing performance with low tension fabric guidance of circular knitted fabrics, warp knitted fabrics, lace or fine woven fabrics - Perfect for your print or color rewash.

Bleaching Machines

Glacier White. With Menzel bleaching plants, we lay the foundation worldwide for economical textile finishing of materials made of cotton, linen, cotton / elastane and polyester / cotton. These qualities are processed, for example, into high-quality fashionable outerwear or workwear. Trouser fabrics, uniform fabrics, bed linen and fabrics for shirts are just as much a part of the production spectrum of a Menzel woven fabric bleaching plant as the finest table linen, damask or even satin. Menzel Maschinenfabrik even offers suitable knitwear bleaching plants for sensitive knitwear made of cotton.

Menzel bleaching plants are your guarantee for reproducible bleaching results and high productivity, even for delicate articles. Regardless of the application: continuous knitwear bleaching systems, single-stage and two-stage steaming bleaching systems for woven fabrics, pad-roll hot bleaching systems or even KKV bleaching systems. Maximum application systems, addition application or impregnation according to the exchange method, we provide the best possible solution that exactly fits your material.

We will be happy to advise you on the individual design and composition of your system, according to your needs.

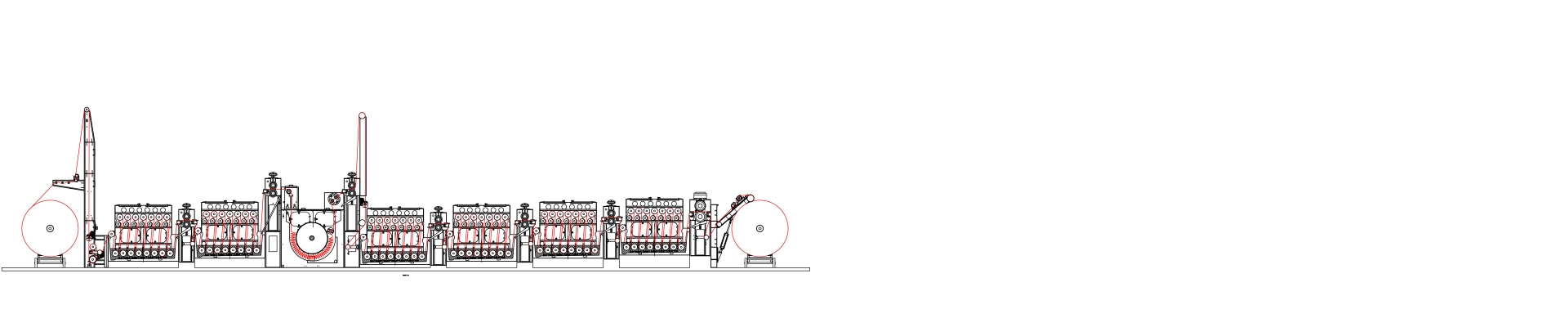

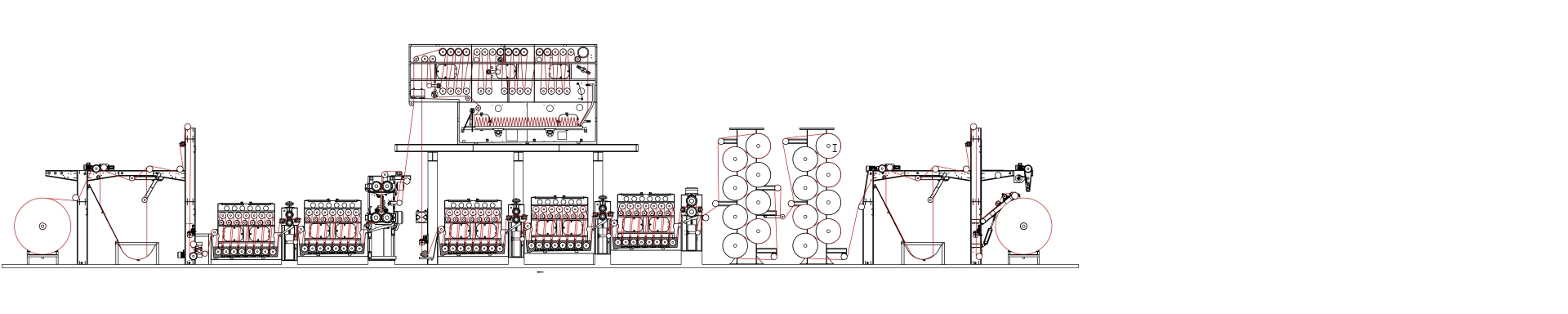

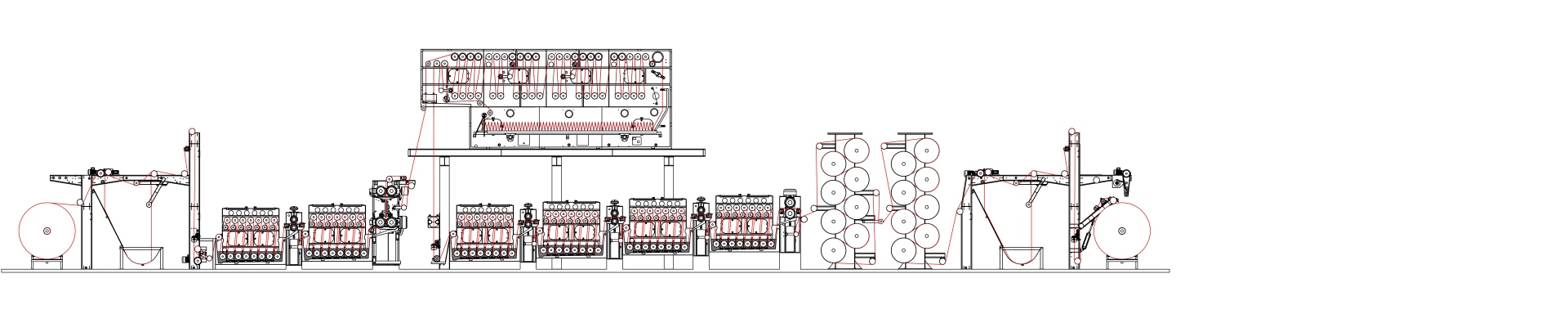

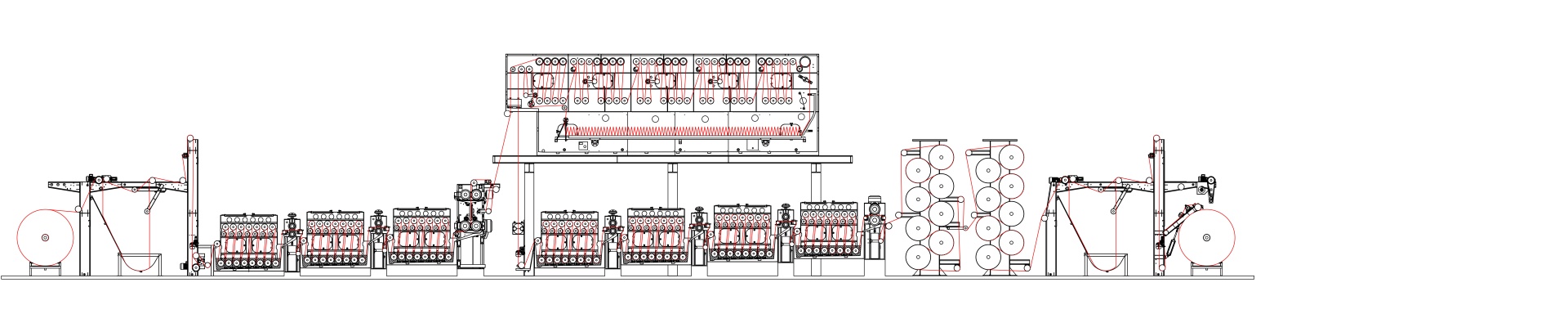

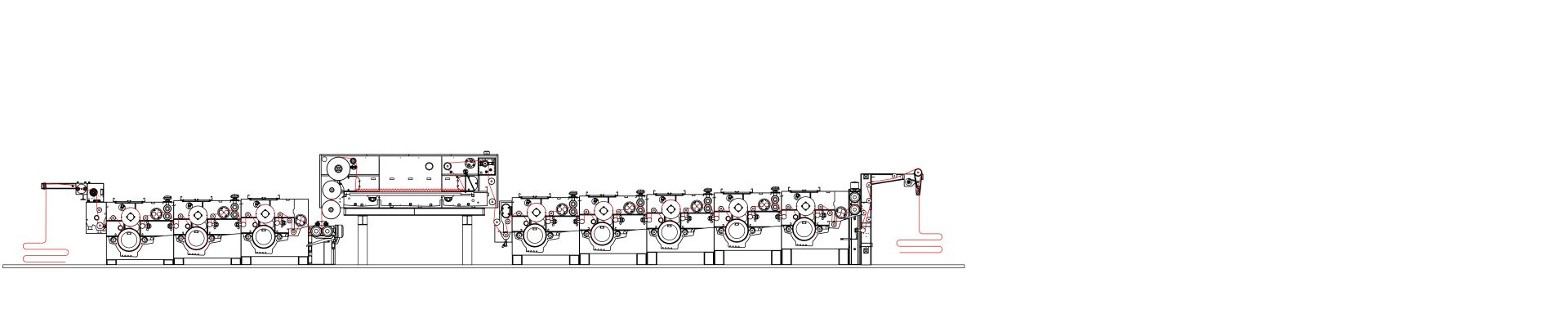

Bleaching machine Pad Roll

Bleaching machine OPTIBLEACH S

Menzel bleaching plants are designed individually to your requirements according to the modular system. The OPTIBLEACH S is a continuously operating wide bleaching plant. It was designed for small to medium fabric quantities and allows combined boiling off and bleaching up to a speed of 50 m/min.

Bleaching machine OPTIBLEACH M

The Menzel Optibleach M continuous wide bleaching line was designed for medium production quantities up to a speed of 70 m/min. Boiling-off and bleaching are combined in one step.

Bleaching machine OPTIBLEACH L

The Menzel Optibleach L is a continuous wide bleaching plant for large production quantities up to a speed of 100 m/min. Boil-off and bleaching take place in one step.

Bleaching machine OPTIBLEACH XL

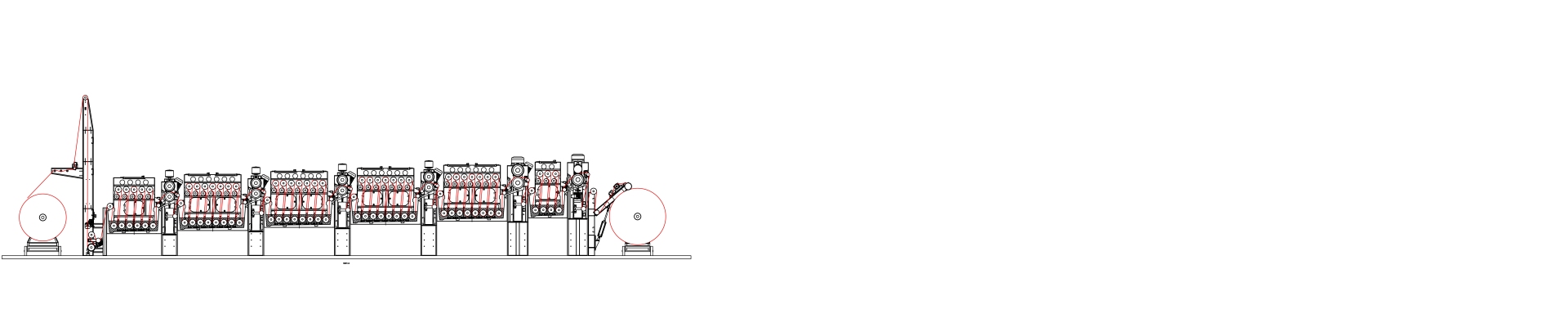

Bleaching machine OPTIBLEACH KF

Bleaching plant for the pretreatment of cotton and cotton blend knitted fabrics which are sensitive to tension and which are to be continuously desized, demineralized and bleached. The plant offers an additional benefit when used for color and print post-washing.

Mercerizing machines

Perfect gloss and high dye absorption. Menzel mercerizing lines set worldwide standards in the field of mercerizing high-quality textiles made of cotton, viscose, linen or cotton-polyester. The better dye absorption and the silky sheen give mercerized fabrics a more noble appearance. Menzel mercerizing lines are also highly automated via the OPTICONTROL process control system.

For all application processes, regardless of whether hot mercerizing, cold mercerizing, wet-on-wet mercerizing or dry-on-wet mercerizing, even for mercerizing shirting fabrics or delicate satins as well as jacquards; Menzel has the best solution for every application.

Menzel offers warp mercerizing units for mercerizing shirting fabrics, the classic roller mercerizing unit for flat woven fabrics as well as combined warp-roller mercerizing units. In addition, the Menzel Minimerc mercerizing machine is a solution for the mercerizing of small batches for woven fabrics.

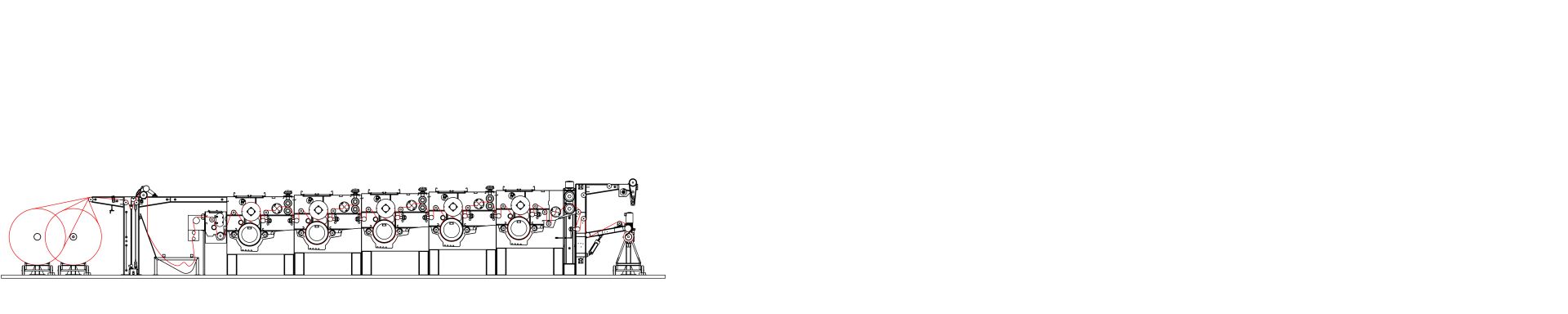

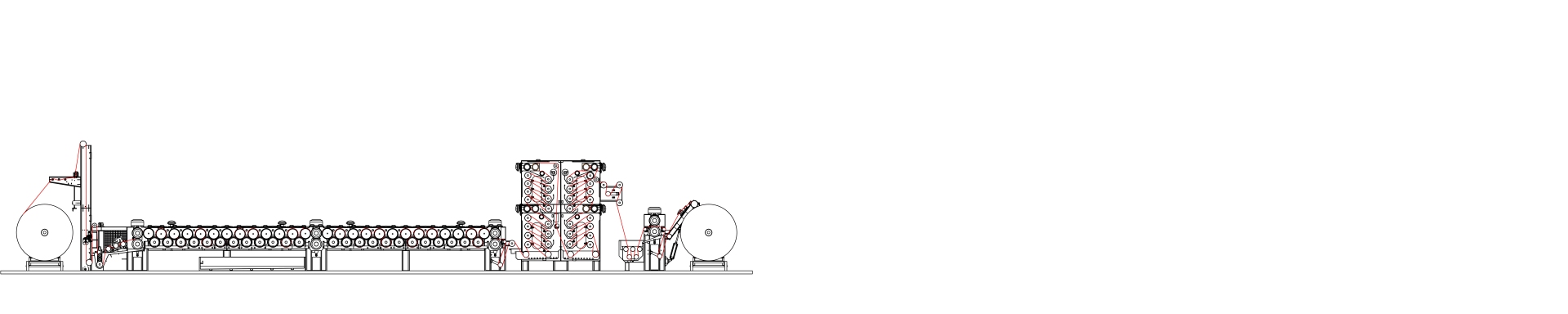

Mercerizing line Minimerc

Mercerizing line Optimerc Chainless

Mercerizing line Optimerc Combi

The OPTIMERC COMBI is a combined roller/warp mercerizing unit: in the mercerizing compartment, the fabric is guided in a bond over rollers, the stabilizing compartment consists of a warp field or a warp field and roller compartment. It is particularly suitable for mercerizing yarn-dyed fabric.

Mercerizing line Optimerc Chainmaster

Dyeing Machines

We add the splash of colour. A large proportion of the textiles finished worldwide are dyed continuously. The dyeing is always done in a combination of dye application and a dye fixation, be it by temperature in the thermosol process, by saturated steam in the pad-steam process or via the factor of time in the cold dwell process.

Menzel Maschinenbau offers the Opticolour S-roller dyeing foulard as the core element of a dyeing system. It is suitable for the application of reactive dyes, direct dyes, vat dyes, sulfur dyes or disperse dyes. In combination with state-of-the-art and high-precision dosing systems, the name Menzel stands for reproducibility and precision.

Our product range offers individual solutions for dyeing cotton or viscose with reactive dyes according to the KKV process for knitted and woven fabrics as well as complex pad steam dyeing systems for dyeing workwear, trouser fabrics or denim with vat dyes or sulfur dyes.

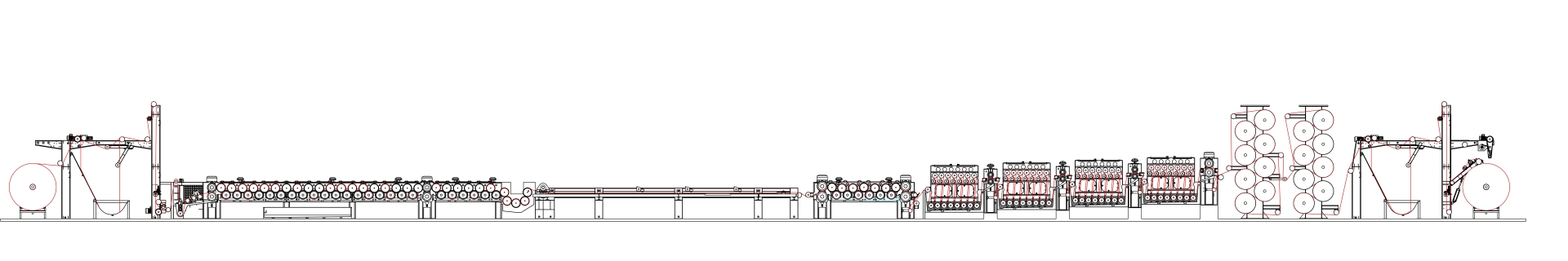

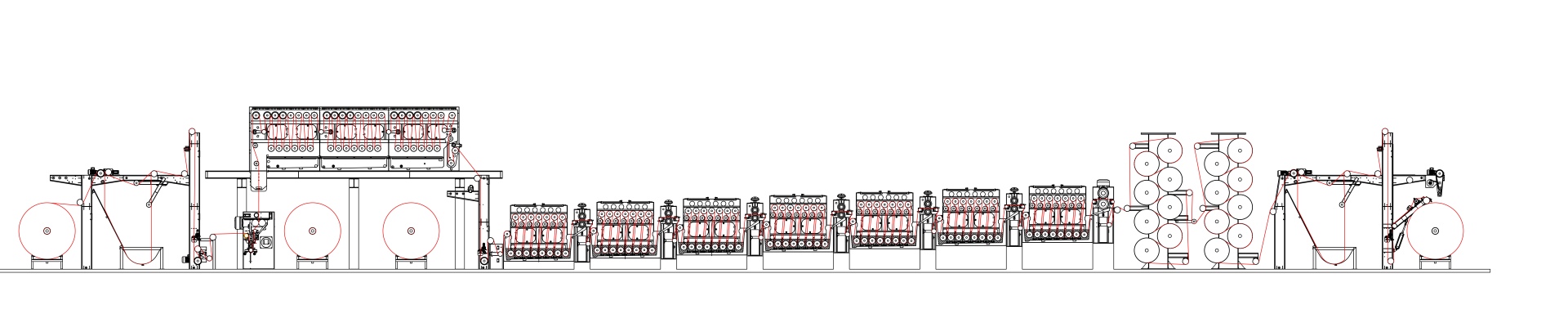

Dyeing machine KKV Opticolour

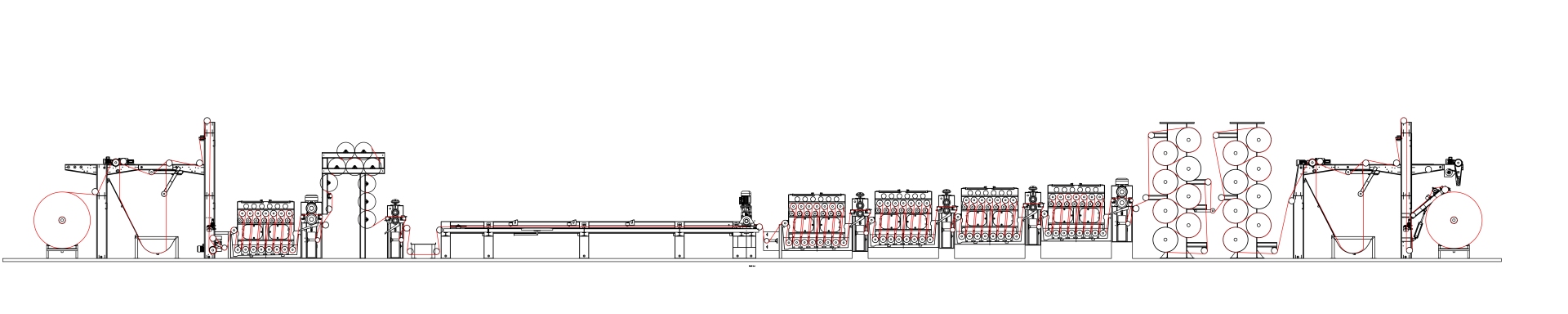

Dyeing machine Pad Steam

The OPTIDYE WF is a pad-steam dyeing machine for woven fabrics, which stands for high production output with excellent fabric quality.

Dyeing machine Pad Dry

Continuous thermosol dyeing system with MENZEL OPTIDYE, infrared dryer and hotflue: Precisely controlled temperatures and synchronized dye application allow constant fixation of your dyes for brilliant results.

Aggregates and accessories for wet machines

We realize YOUR project!

Do you need more information? We look forward to hearing from you!