Rewinding and cutting

Many materials are converted into customer rolls after the actual manufacturing process. Our Menzel rewinding and slitting lines were developed to combine these two process steps. The high-speed machines feature material-adapted slitter systems as well as automatic reel change systems.

In addition, winding with and without cores is possible, as is the insertion of labels. The rolls can then be pushed off automatically. Furthermore, you can optionally extend your line with banding devices and edge strip winders. The examples on this page show the different systems we have already realized. We would be pleased to offer you an individual solution for your challenge!

Rewinding and cutting machines for short reels

Rewinding machines for the production of small reels for sale to the end user: Your goods are effectively rewound on our equipment with the usual Menzel quality. Whether narrower cores or other diameters, we offer the right solution for your product!

Automatic short reel winder 1-winding position for nonwoven

Fully automatic short roll winder with slitting device. Up to seven rolls can be wound and banded side by side.

Automatic short reel winder 3-winding positions for plaster reinforcing fabric

The automatic rewinding line is specially designed for the production of small rolls of technical fabrics and nonwovens.

Automatic short reel winder with support roller for pvc film

Heavy roofing foils are converted on this rewinding line. It is equipped with a slitting device for trimming the material web and a delivery table.

Short reel winder 2-winding positions for nonwoven

The slitting rewinder has been specially designed for narrow nonwoven rolls and has two rewinding stations, a push-off unit and edge trim suction.

Rewinding and cutting machines with support roll winder

Automatic rewinding and cutting machine for banner fabric

Fabric foaming machine and rewinding line with a roller width of up to 5,400 mm for the special requirements of the production of banner goods and billboards

Rewind cutting machine for abrasive carrier

Rewinding machine for particularly high tensile stresses and very high winding hardnesses. The finished roll is lifted out of the winder and placed on a pallet.

automatic rewinding and slitting machine for nonwovens

Rewinding machine for nonwovens with automatic winding shaft handling, as well as inspection table with defect winder.

automatic support roll winder for roofing underlays

Rewinding and slitting machine with automatic core magazine for lightweight nonwovens and roofing underlayments up to 350 g/sqm.

Fully automatic rewinding and slitting machine for nonwovens

Fully automatic rewinding machine with speeds up to 500 m/min and semi-automatic knife adjustment.

Rewinding and cutting machine for interlining material

Rewinding machine with longitudinal cutting device and integrated inspection table especially for the fabric inspection of sensitive lightweight nonwovens.

Rewinding and cutting machine for textiles inspection

Circumferential winder with additional center drive and automatic roll deposit on pallet.

Rewinding and inspection machine for wallpaper

This carrier roll winder with inspection machine is used for the finishing and quality control of wallpaper.

Rewinding and foaming inspection machine for technical textiles

Rewinding machine with calibrated length measurement for high quality goods on a tension-free running surface.

Rewinding and slitting machines with center winder

Center winders are used for unwinding and rewinding pressure-sensitive materials such as films and nonwovens. In combination with our foam machines, quality control and thus technically flawless products are guaranteed.

Rewinding and cutting machine for plaster reinforcement fabric, 1-winding position

Rewinding machine with edge-controlled unwinding and slitting unit with shear cut.

Rewinding and cutting machine for glass fleece, calibration model

Cutting unit for narrow webs on swiveling winding shaft

rewinding and slitting machine for nonwovens

Rewinding unit with welding bars for splicing as well as shear cut unit and center winder with high tensile stresses.

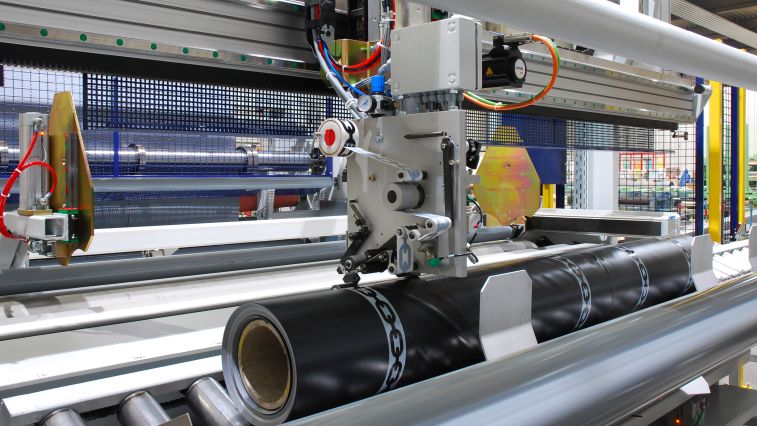

Rewinding and cutting machine for PVB film

Rewinding and slitting line for converting PVB film for use as glass interlayer in the construction or automotive industries

Rewinding and inspection machine with impregnation device

Rewinding and impregnation line for sensitive, technical textiles with fabric foaming machine for quality inspection

Rewinding and foaming inspection machine for technical textiles

Rewinding and inspection machine for quality control of technical textiles - for technically flawless products.

Rewinding and cutting machine for laminates

Rewinding and slitting line for coated papers and cardboards

Rewinding machine for small reels

Manual rewinding machine with rotating frame control for easy removal of defects in the material.

Rewinding and cutting machine for conveyor belts

Rewinding and cutting machine for heavy conveyor belts with special retracting device.

Cutting systems

Menzel winding machines can of course also be equipped with slitters. The cutting methods used are shear cut, blade cut, crush cut, burst cut or ultrasonic cut. In addition to standard winders, we also supply winding systems tailored to your materials and requirements.

Scissor cutting device

Manual knife adjustment with laser-assisted positioning for upper and lower knives.

Cutting system with automatic motorized adjustment

Crush cutting unit with automatic motorized single knife adjustment as well as parking position for knives.

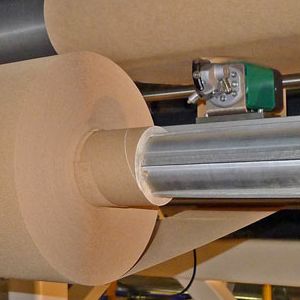

Crush cutting device for glass mats

Cutting unit especially for narrow webs on swiveling winding shaft

Crush cutting device for nonwoven

Semi-automatic knife adjustment for widths up to 3,600 mm

Oscillating blade cutting device

Ultrasonic cutting unit

Cutting device for precise cutting without fraying of nonwovens, films, textiles and composites

Burst cut device

Cutting of structured foils as well as bituminous sheets with special rotating circular knives using the burst cutting method.

Aggregates and accessories for rewinding and cutting machines

We realize YOUR project!

Do you need more information? We look forward to hearing from you!