Production

Quality made in Germany

We manufacture with highly qualified employees at three locations in Germany. From welded design and sheet metal processing in our stainless steel competence center to the production-ready plant, we cover the entire manufacturing chain from a single source.

The highest quality standards are the value yardstick in the individual production processes at all times. Only in this way can we fulfill our guarantee promise and the expectations of our customers. Economic efficiency and ecological requirements are strictly checked during the production stages: in the Menzel plants as well as at our suppliers.

Each plant is completely assembled by our assembly teams before delivery. Spacious assembly halls allow us to test and trial under production-like conditions. Menzel thus ensures functional reliability as well as short assembly and commissioning phases at the installation site.

Component manufacture

As a contract manufacturer, we assemble complete assemblies and plants according to the customer's engineering. We also undertake the production of individual parts.

Large CNC parts machining

The swiveling milling head of our portal milling machine enables the majority of machining from 5 sides without reclamping.

Stainless steel processing

Our production facility in Bielefeld-Brackwede processes stainless steel in a material thickness range between 1 mm and 15 mm.

CNC turning

Contract manufacturing of large rolls is our competence: up to a center width of 7,500 mm and a workpiece diameter of 800 mm.

Paint shop

On request, we can coat your metal construction parts in our own paint shop. The color is possible according to RAL color chart.

Quality inspection

The dimensional control of the workpieces during and after production is a matter of course for us. During the entire manufacturing process, all our employees involved guarantee the quality of the final product.

Stainless steel blasting

In addition to the fatigue strength and improved corrosion resistance of welds treated by surface blasting, the stainless steel shot peening process produces a particularly high-quality workpiece appearance.

Our large CNC portal milling machine ensures the economical machining of large steel assemblies up to 13,500 mm in one clamping without expensive reclamping of the workpieces.

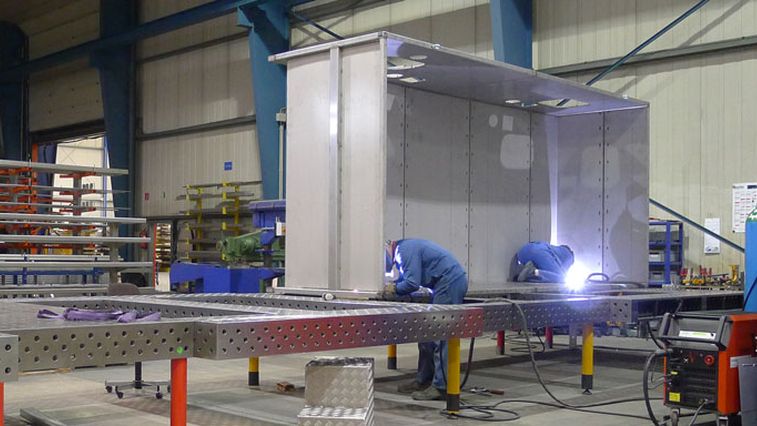

Welding

As a component supplier for mechanical engineering in the East Westphalia region, our range of services includes welded constructions as individual parts or complete assemblies, which are manufactured according to customer drawings.

Switch cabinet construction

In our in-house control cabinet construction, we manufacture complex switchgear for our special machines. This is how we ensure quality and fast response times.

Laser cutting

Our laser cutting systems enable the processing of stainless steel sheets and aluminum parts up to 15 mm thick. We can efficiently process maxi formats up to 4,000 mm x 2,000 mm with these systems.

Plasma cutting

High quality cuts: plasma cutting allows processing medium and thick sheets at high speed and high precision of cuts at low cost.

We realize YOUR project!

Do you need more information? We look forward to hearing from you!